Omron Human Machine Interfaces (HMI)

Navigating Precision: The Power of Omron Human Machine Interfaces in Industrial Automation”

As a global supplier of OMRON Human Machine Interfaces (HMI) solutions and high-reliability industrial touch screen technology for over 12 years, Omron has supplied more than 500,000 pieces of HMI through more than 200 world-wide sales and support offices each offering after-sales support, service and training in the local language.

In the dynamic landscape of industrial automation, Human Machine Interfaces (HMIs) play a critical role in bridging the gap between human operators and complex automated systems. Omron, a trailblazer in innovative automation solutions, introduces an unparalleled suite of Human Machine Interfaces designed to elevate user experience, precision control, and operational efficiency in industrial settings.

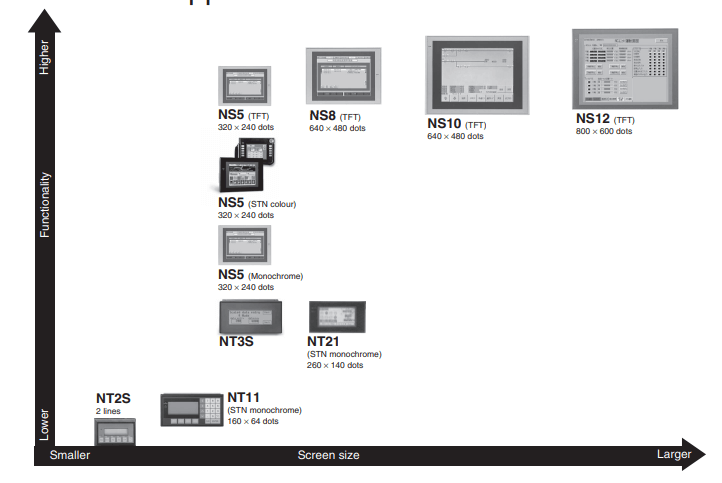

The wide range of NT- and NS-series HMIs suits most applications.

NS series Advanced Touch Screens

The Omron Human Machine Interfaces CX-Designer is used to create screen data for NS-series Programmable Terminals. The CX-Designer can also be used to test

the operation of the created screen data on the computer.

Screen Creation

Develop Screens More Efficiently with Easy-to-use Support Software.

The Omron Human Machine Interfaces CX-Designer has about 1,000 standard functional objects with

associated graphics and advanced functions, so even first-time users

can create screens easily just by arranging functional objects in a

screen.

The Omron Human Machine Interfaces CX-Designer is also equipped with a variety of functions that make

it easy to create screens for common applications. Screen

development is very efficient with the CX-Designer.

Screen templates

Make one common screen (sheet) that overlaps other screens (to save

having to recreate the same part, such as a menu, in every screen).

A feature that is common to several screens can be registered in a

sheet. The common feature can be added to any screen just by

applying the corresponding sheet to the screen. (Up to 10 sheets can

be created for one project.)

NT series Touch Screen

Cost effective touch screen terminals to

replace function key units and increase the

flexibility and operation.

NT series Function Key screens

The NT11, the Slim, Low Cost Operation

Terminal that Stands Up Well to Harsh

Environments.

• Long-lived Backight

• Simplified Ladder Programming

• Password Screens

• Conforms to NEMA4 and IP65

NT-XS series Touch Screen

• 4.1“ monochrome STN LCD with LED backlight

(long lifetime)

• Maximum of two universal (RS232/485/422) serial

ports to connect multiple devices with different protocols at the same time

• Drivers for most PLCs, Inverters and Servo Controllers

• Multiple data entry objects per screen with individual

limit setting and math operations

• Support for floating point data

• Wizards for rapid application development of standard bitmapped objects

• Real-time and historical alarms (historical alarms in

RTC models only)

• Trend graph for defined tags (RTC models only)

• Saves recipes data in non-volatile memory

• Windows® based programming software NT-XS for

free!

• IP65 design, CE / cULus Class 1Div. 2 certification

NT-XS series Function Key Screens

The NT2S series Terminals are designed

as a human machine interface for simple

control tasks. Their small dimensions and

low installation depths ensure that they

will fit into any machine.

Of the six NT2S types, four can be connected

directly to the peripheral port and two can be

connected to OMRON PLCs via an RS-232C

port.

• Easy programming

• Small size and installation depth

• IP65 protection

• Real-time clock

• Printer connection

• Excellent value for money

Omron Human Machine Interfaces: Precision Redefined

Omron’s Human Machine Interfaces stand out as a pinnacle of precision and technological sophistication. These interfaces serve as the visual and tactile gateway for operators, providing a comprehensive platform to monitor, control, and optimize a myriad of industrial processes. Omron HMIs are not just interfaces; they are precision tools engineered to empower operators in their quest for efficient and reliable automation.

Intuitive Design for Seamless Interaction

At the core of Omron Human Machine Interfaces lies an intuitive design that prioritizes user experience. These interfaces are equipped with high-resolution touchscreens, customizable displays, and an interface designed for simplicity. This thoughtful design ensures that operators can navigate seamlessly, fostering quick and accurate decision-making in dynamic industrial environments. Omron HMIs transform complexity into simplicity, making precision control accessible to operators at all levels.

Programming Capabilities Tailored for Versatility

Omron Human Machine Interfaces are not just user-friendly; they are also versatile in their programming capabilities. Supporting various programming languages, including ladder logic and function block diagram, Omron HMIs empower operators to tailor interfaces precisely to the unique needs of their industrial processes. This adaptability positions Omron HMIs as the go-to solution for industries with diverse and evolving automation requirements.

Applications Across Industries

Omron Human Machine Interfaces find applications across a spectrum of industries, including automotive, electronics, pharmaceuticals, and food processing. Whether it’s overseeing manufacturing lines, controlling robotic systems, or monitoring critical processes, Omron HMIs provide a unified platform for operators to visualize and control industrial operations with unparalleled precision. From the shop floor to the control room, Omron HMIs are catalysts for efficiency and productivity.

Connectivity for Smart Manufacturing: Omron HMI Networking Capabilities

In the era of Industry 4.0, connectivity is not just a feature; it’s a necessity for smart and responsive industrial systems. Omron Human Machine Interfaces are designed with advanced communication protocols, including Ethernet and serial communication options. This level of connectivity ensures seamless integration into interconnected industrial networks, enabling real-time data exchange and contributing to more intelligent and connected industrial environments. Omron HMIs are not just interfaces; they are enablers of the connected future.

Safety and Reliability at the Core of Omron HMIs

Safety is non-negotiable in industrial automation, and Omron HMIs prioritize this aspect with advanced safety features. Built to withstand demanding conditions, these interfaces ensure reliable operation in challenging environments. The robust construction of Omron Human Machine Interfaces underscores their longevity, making them a trusted choice for industries where consistent and dependable performance is paramount. With Omron HMIs, operators can trust in the reliability of their automation systems.

Comprehensive Support and Training Resources

Omron goes above and beyond in delivering not just products but a holistic user experience. Operators utilizing Omron Human Machine Interfaces have access to comprehensive training resources and documentation. This support system ensures that users can maximize the capabilities of Omron HMIs, from mastering programming intricacies to troubleshooting, enhancing the overall efficiency of industrial processes. Omron is not just a provider of interfaces; it is a partner in the journey towards automation excellence.