In the era of industrial automation, communication protocols serve as the “common language” that helps devices and systems communicate effectively. From transmitting accurate data to optimizing production processes, communication protocols are indispensable to ensure stable and safe operation for any system.

Introduction to Communication Protocols

Communication Protocols, also known as communication protocols, are rules established to ensure data transmission between devices in a system. In the automation industry, these protocols play a Working environment: Choose the protocol suitable for environmental conditions such as temperature, humidity, and electromagnetic interference. core role, helping to connect PLCs, HMIs, SCADAs, sensors, and other devices smoothly.

With the trend of integrating the Internet of Things (IoT) and Industrial IoT (IIoT) systems, communication protocols have become one of the key factors helping businesses optimize processes and accelerate digital transformation.

What are Communication Protocols?

How Communication Protocols Work?

Communication Protocols establish rules and standards to ensure data transmission between devices is accurate and efficient. Their basic working principle includes the following 7 steps:

Step 1: Divide data into packets

Data to be transmitted is divided into small packets called packets or frames, each containing data information, source address, destination address, and error checking information.

Step 2: Encode data

Data is encoded in a specific format that both the sending and receiving devices understand, ensuring the ability to read the correct content when it arrives.

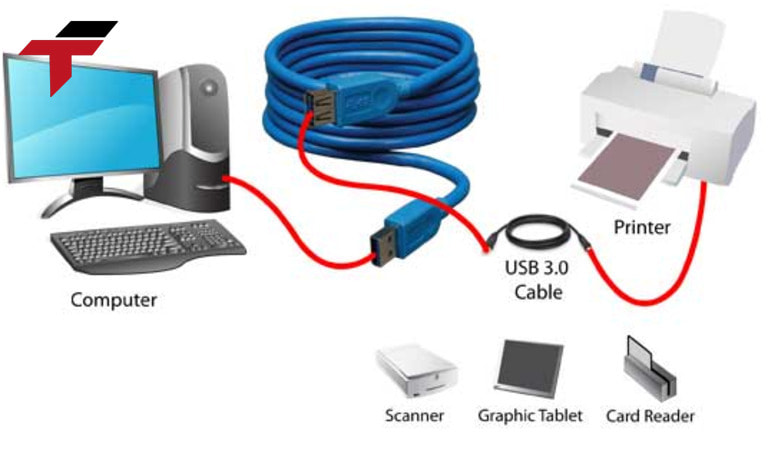

Step 3: Transmit packets over the media

Data is transmitted over physical media such as network cables (Ethernet), radio waves (Wi-Fi, Zigbee), or serial connections such as RS-232, RS-485.

Step 4: Receive and Decode Data

The receiving device decodes the packet according to the protocol rules, ensuring that the content is restored exactly as the original data.

Step 5: Error checking and acknowledgment

The packet is checked for errors through checksum or parity bits. If there are no errors, the receiving device sends an acknowledgment signal (ACK) to the sending device.

Step 6: Feedback and processing

The data is processed and responded to if necessary. Some protocols support two-way communication, allowing the sending and receiving devices to communicate simultaneously.

Operating principle of Communication Protocols

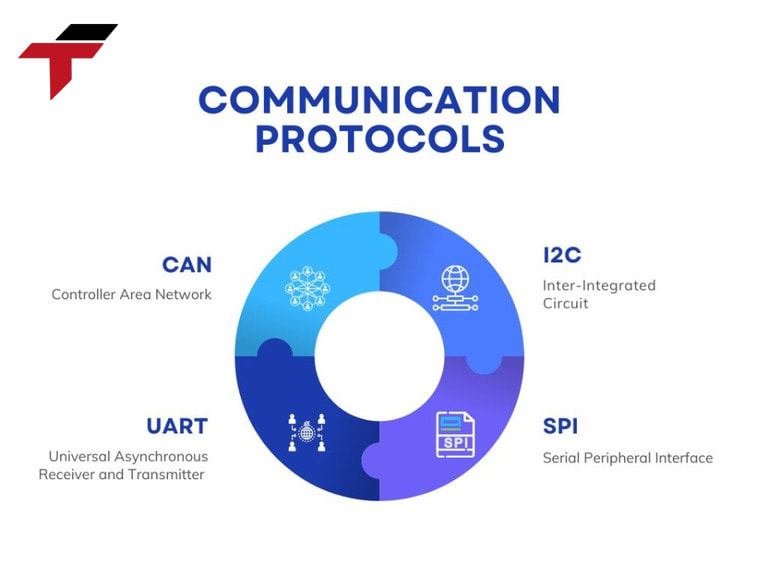

How many types of Communication Protocols are there?

Fieldbus Protocols

Fieldbus Protocols are a group of communication protocols that span field-level devices. They help connect sensors, actuators, and PLCs.

- Modbus: Developed by Siemens, PROFIBUS supports high-speed and reliable data transmission. It is commonly used in manufacturing and process automation.

- Profibus: Simple, flexible and easy to integrate. Modbus supports both serial (RS-232/RS-485) and Ethernet communication.

- Canbus: Designed for environments requiring high reliability, especially in the automotive and heavy industry.

Industrial Ethernet Protocols

Industrial Ethernet Protocols provide faster and longer data transmission than traditional communication protocols.

- Ethernet/IP: Widely used for real-time control and industrial information applications.

- Profinet: Ethernet version of PROFIBUS, supporting high-speed communication and good integration with automation devices.

- EtherCAT: High-performance Ethernet protocol, optimized for systems requiring extremely fast response times.

Wireless Communication Protocols

Due to their flexibility, wireless protocols have become the optimal solution in environments where wiring is difficult.

- Zigbee: An energy-efficient protocol, commonly used in wireless sensor systems.

- Bluetooth: Integrated in compact devices, supporting short-distance communication.

- Wifi: Used for applications that do not require low latency, suitable for office and factory environments.

IoT and IIoT Protocols

With the growth of the Industrial Internet of Things (IIoT), specialized protocols have emerged to connect devices and exchange data over the internet.

- MQTT: Lightweight protocol, ideal for data transmission in resource-constrained devices.

- CoAP: Optimized for small devices in IoT networks, using a model similar to HTTP.

- AMQP: Secure and reliable messaging protocol, used in large systems.

Common types of Communication Protocols

What are the Benefits of Communication Protocols?

Using communication protocols in industrial automation offers many significant benefits, including:

- Increased compatibility: Standardized communication protocols allow devices from different manufacturers to connect and work together easily.

- Improved operational efficiency: Fast and accurate data transmission helps automation systems respond better, reducing downtime and optimizing production processes.

- Support remote control and monitoring: Protocols such as Ethernet or IoT enable remote management and control of devices, improving overall control.

- High flexibility: Supports flexible system configurations, from wired to wireless connections, suitable for many different working environments.

- Cost savings: Using a common protocol reduces deployment and maintenance costs while leveraging existing devices without replacing the entire system.

- Enhanced security: Many modern protocols incorporate robust security features, such as encryption and authentication, that help protect data from cyber threats.

Benefits of Communication Protocols

What are the important considerations when choosing a communication protocol?

Choosing the right communication protocol plays an important role in ensuring the performance and reliability of an industrial automation system. To make the optimal decision, consider the following factors:

- Compatibility with existing equipment: Make sure that the selected communication protocol is compatible with the existing equipment in the system.

- Data transmission speed and bandwidth: For applications that do not require very high data transmission speeds, such as environmental monitoring, simple protocols such as Modbus or Zigbee may be sufficient.

- Communication range: If the system needs to connect over long distances or between factories, wireless protocols such as Wi-Fi or Zigbee may be the ideal choice.

- Data security: In IoT environments or public networks, prioritize protocols that integrate strong security features such as encryption and authentication.

- Working environment: Choose the protocol suitable for environmental conditions such as temperature, humidity, electromagnetic interference.

The above notes will help you choose the appropriate communication protocol, meeting both technical and financial requirements, thereby optimizing the operation of the automation system.

Conclusion

Communication Protocols are the core foundation that helps businesses in the automation industry improve efficiency and accuracy. Investing in researching and applying communication protocols properly will bring many sustainable values to businesses.

Understanding and choosing the right protocol is key to building a sustainable system that meets modern industrial requirements.