Brain-computer interface (BCI) is opening a new era in the field of automation, allowing people to interact with machines without physical manipulation. This technology not only optimizes the production process but also supports remote control of equipment, improves productivity and opens up opportunities for people with disabilities to participate in labor. So how does BCI work? What benefits does it bring to the industry? Let’s find out in detail in the article below.

What is a Brain-Computer Interface (BCI)?

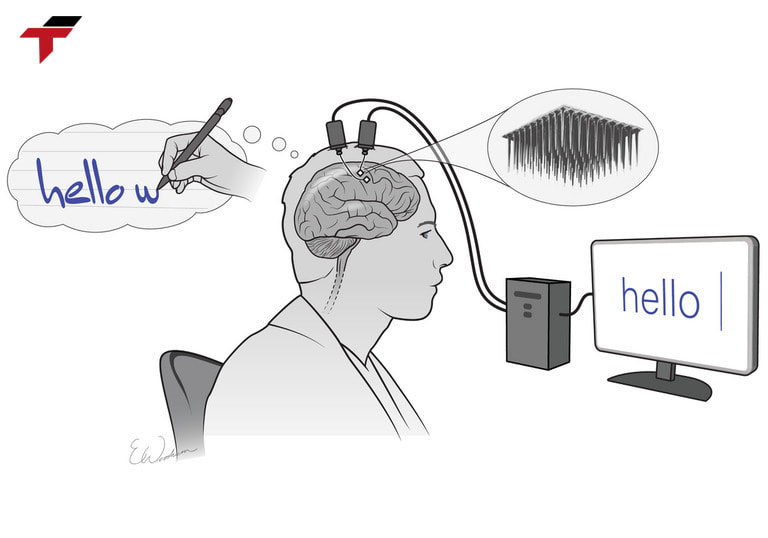

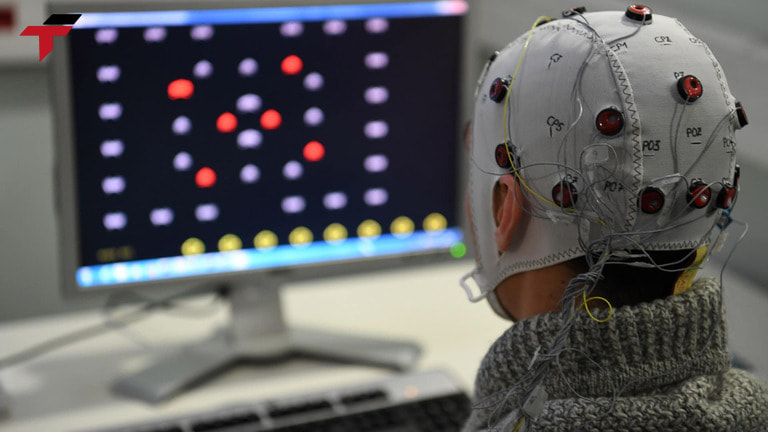

A Brain-Computer Interface (BCI), or brain-computer interface, is a technology that connects the human brain directly to a computer system or control device without the need for traditional input devices such as a keyboard, mouse, or voice.

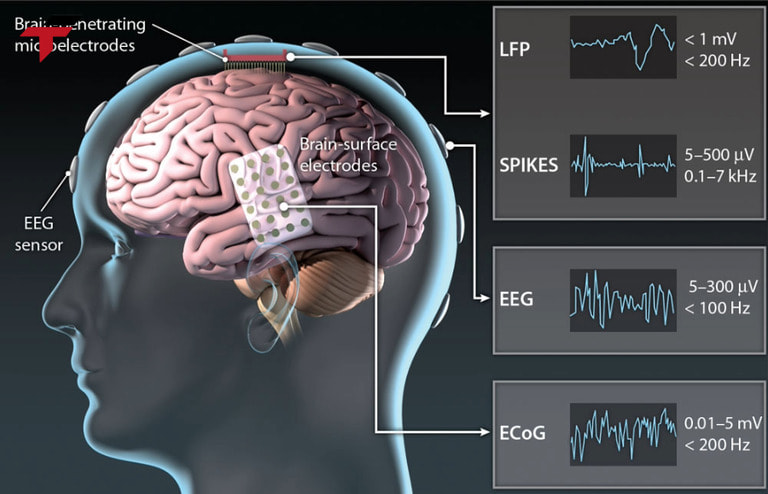

BCI captures, processes, and converts bioelectrical signals from the brain into control commands for external devices. This technology often uses methods such as electroencephalography (EEG), electrocortical encephalography (ECoG), and functional magnetic resonance imaging (fMRI) to read brain signals and translate them into usable data.

What is a Brain-Computer Interface (BCI)?

What are the benefits of Brain-Computer Interface for businesses?

Brain-Computer Interface (BCI) is not only a step forward in neurotechnology but also brings many breakthrough benefits in the field of automation. Thanks to the ability to directly connect the brain and machines, BCI helps optimize production processes, improve work efficiency, and open up completely new control methods.

Let’s find out with Flextech what benefits this technology brings to the industry?

- Increase production efficiency: Workers can control machines faster with their thoughts, reducing operating time compared to traditional methods.

- Increase accuracy: Reduce errors due to manual operations thanks to precise control signals from the brain. Integrate with AI and IoT to optimize automation in smart factories.

- Support remote device control: BCI can be applied to control robots, autonomous vehicles (AGVs),and industrial drones, helping to manage material transportation more effectively.

- Reduce dependence on physical operations: BCI helps operate machines without using hands, suitable for harsh or dangerous production environments. Support people with disabilities to participate in production processes, expanding the labor force.

BCI helps optimize production processes, improve work efficiency, and open up completely new control methods.

What are the challenges of Brain-Computer Interface in automation?

- Signal latency: Brain signals are very complex, easily affected by electromagnetic interference or the user’s mental state.

- High investment costs: BCI systems require advanced technology to capture and process signals, resulting in high hardware and software costs. Large-scale factory deployments require long-term investments and continuous upgrades.

- Security and privacy issues: BCIs collect data directly from the brain, making them vulnerable to hacking or data theft, raising security concerns.

- Scalability and integration: Integrating BCIs into existing automation systems can be technically challenging.

In summary, BCIs offer many potential benefits for automation, but also pose many technical, ethical, and social challenges. Addressing these challenges is critical for BCIs to be widely adopted and benefit society.

What is the role of Brain-Computer Interface in industrial automation?

In the industrial automation industry, BCI plays an important role in improving production efficiency, optimizing workflows, and creating smarter systems. Some of the key roles of BCI include:

- Controlling equipment with thoughts: Operators can control robotic arms, machines, or production lines using only brain signals, increasing work efficiency and reducing dependence on physical manipulation.

- Monitoring and optimizing production processes: The system can analyze the operator’s mental state to adjust the working environment, reduce stress, and increase productivity.

- Automating medical assistance: BCI helps operate assistive devices in manufacturing and rehabilitation, especially in factories that manufacture medical devices or perform robotic surgery.

Thanks to its huge potential, BCI is gradually changing the way people interact with automation systems, opening a new era for smart factories and modern manufacturing.

BCI plays an important role in improving production efficiency, optimizing workflows, and creating smarter systems.

Comparison of Brain-Computer Interface (BCI) and Human Interface Device (HID) in Automation

| Brain-computer interface (BCI) | Human Interface Device (HID) | |

| Definition | Interface that connects directly between the brain and a computer/machine, without physical manipulation. | Intermediate devices that help humans control machines, such as keyboards, mice, touch screens, joysticks. |

| How it works | Receive signals from the brain and convert them into control commands. | Users enter commands by hand or body movements. |

| Response speed | Fast, no physical manipulation required. | Depends on the user’s manipulation speed. |

| Accuracy | High but easily disturbed by mental state. | Very high, direct physical manipulation helps avoid errors caused by signal interference. |

| Popularity | New technology, not widely used due to high cost. | Very common in most automation systems. |

| Industrial applications | Robot control, worker status monitoring, support for the disabled. | Machine control via touch screen, joystick, keyboard… |

Conclusion

Brain-computer interface (BCI) is gradually asserting its important role in the field of automation, allowing people to control machines quickly and accurately with just their thoughts.

This technology not only helps optimize production processes but also opens up new access opportunities for workers, especially in harsh environments or those requiring high precision.

In the future, when combined with AI, IoT and robots, BCI can become an indispensable part of smart factories, helping businesses increase flexibility, reduce operating costs and improve productivity.