In the automation industry, the Human Interface Device (HID) plays an important role in connecting people with machines, making the operation process more intuitive, accurate and efficient. From touch screens, industrial keyboards to remote control devices, HID supports monitoring and optimizes the production process. So what is Human Interface Device, what types are there and how are they applied in the factory? Let’s find out the details in this article!

What is a Human Interface Device (HID)?

Human Interface Device (HID) is a term for input and output devices that allow humans to interact with machines, automation systems, or computers. HID acts as an intermediary, helping users send control commands and receive feedback from the system, supporting optimal workflow, improving performance and ensuring safety in operation.

How many common types of Human Interface Devices are there?

In the field of automation, Human Interface Devices (HIDs) are divided into many types depending on their function and how they interact with the system. Here are some common types of HIDs:

Input Devices: These devices allow operators to enter commands or data into the control system.

- Industrial Keyboards: Used in harsh environments to enter data or control machinery.

- Industrial Mouse/Trackball: Supports precise operations on the control interface.

- Touchscreen Panels: Allow users to enter commands directly via the touch interface.

Output Devices: This group of devices helps display information and feedback system status to the operator.

- Human-Machine Interface: Displays real-time data and provides an interactive interface with the automation system.

- Signal Lights & Buzzers: Warns of problems or notifies the operating status of the production line.

- Industrial LED Displays: Display production information, alerts, and critical operating indicators.

HIDs are designed to suit specific automation applications, from data entry, and information display, to remote control. Choosing the right HID helps businesses optimize operating processes, increase accuracy, and improve production efficiency.

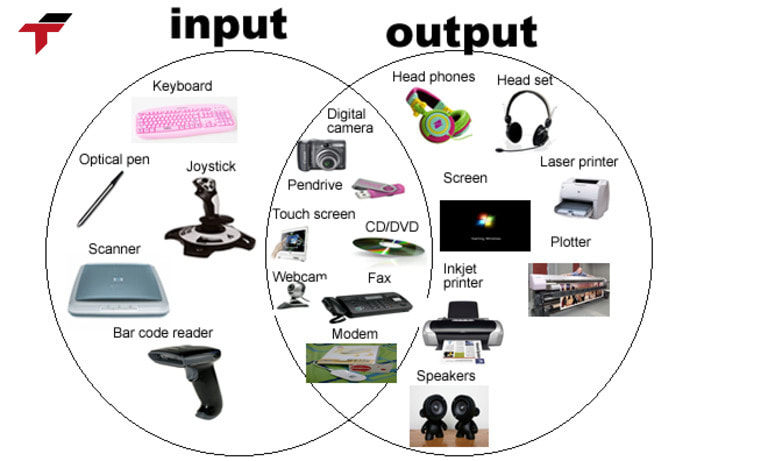

Human interface devices (HID) are divided into two types: Input Devices and Output Devices.

How important is Human Interface Device in the field of automation?

As a bridge between humans and control systems, Human Interface Device (HID) not only helps optimize operating processes but also brings many important benefits to businesses.

- Connecting humans and machines: HID is a bridge, helping operators understand the operating status of machines and make appropriate decisions.

- Visual information display: HID provides important information about the production process, making it easy for operators to monitor and control.

- Remote control and monitoring capabilities: HID allows operators to control machines and monitor production processes from anywhere, minimizing downtime and increasing operational efficiency.

- Ensuring safety: HID provides timely warnings and notifications, helping to prevent accidents and protect workers.

- Increased work efficiency: HID reduces manual operation time, automates some important functions to reduce human error.

Benefits of Human interface device (HID)

What are the notes when using Human Interface Device (HID)?

Businesses need to consider some important factors when using human interface devices (HID) in automation systems to ensure operating performance, equipment durability, and user safety.

- Choose an HID suitable for the working environment: For harsh industrial environments, choose an HID that is dustproof, waterproof (IP65, IP67 standards), and resistant to vibration.

- Ensure device accuracy and sensitivity: With touch screens, periodic calibration is required to ensure accurate operation.

- Periodic maintenance and cleaning: Clean the touch screen surface, keyboard and control devices to avoid dust accumulation, affecting operations. Periodically check the connection wiring system, power source, and data transmission signal to avoid connection errors or operational interruptions.

- Ensure safety when using: Important control devices (HMI, joystick, remote control) should be password protected or have access rights to avoid incorrect operations or intrusion.

- Update and upgrade devices when necessary: HID technology is constantly improving, and businesses should upgrade software and hardware periodically to take advantage of new features and improve operational efficiency.

Choose an HID suitable for the working environment

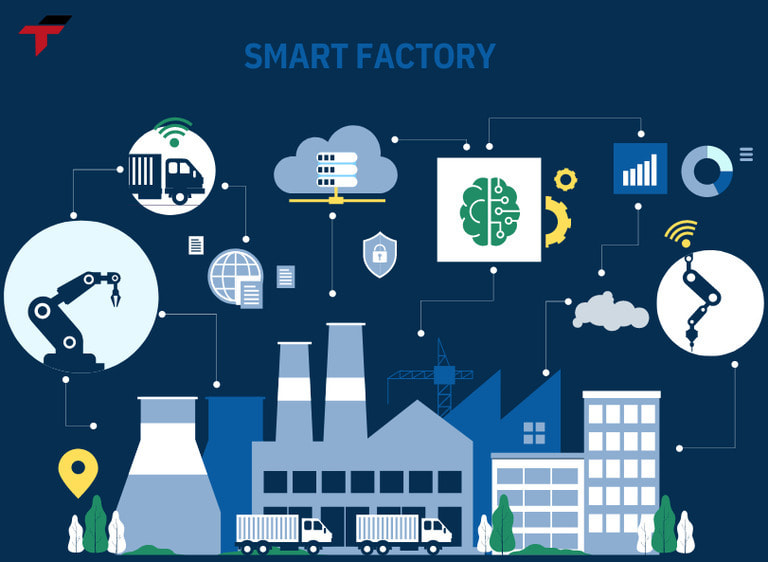

What are the practical applications of Human Interface Device in automated production lines?

Industrial robot control: HID allows operators to program, control and monitor robots in various production stages such as welding, painting, assembly. Touch screens and industrial keyboards are often used to enter commands and monitor the operating status of robots.

Supervisory Control and Data Acquisition (SCADA) system monitoring and control: HID provides an intuitive interface to monitor and control important system parameters such as temperature, pressure, flow. This helps operators easily detect and fix problems, ensuring stable production processes.

Material management and coordination: HID helps monitor and coordinate materials in warehouses and on production lines. The screen displays information about the quantity, location and status of materials, making it easy for operators to manage and coordinate.

Product quality inspection: HID allows operators to perform product quality inspection quickly and accurately. Touch screens and measuring devices are connected to the HID system, helping to collect and analyze data, detect errors and ensure product quality.

Maintenance and repair: HID provides information about machine status, helping maintenance personnel easily identify and fix problems. The screen displays information about errors, and repair instructions, helping to minimize downtime and maintenance costs.

In short, HID plays an important role in automated production lines, helping to control, monitor, manage materials, inspect quality, and maintain machinery. Thanks to that, businesses can optimize operations, improve efficiency, and ensure stable production processes.

How is human interface device applied?

Conclusion

Human Interface Device (HID) plays an important role in the automation industry, helping people easily interact and control machines accurately and effectively. The application of HID in factories not only improves work efficiency but also ensures safety and minimizes risks in operation.