Programmable Logic Controller (PLC) is an abbreviation for Programmable Logic Controller, which is a specialized controller commonly used in large-scale production processes in the automation industry. This device will support users to organize, process, and strictly monitor the stages taking place in the process and can easily detect abnormalities in the chain if any.

Do you know how many types of PLCs there are? Rest assured that when you follow this article to the end, you will have a deep understanding of all types of PLCs, their outstanding advantages in the industry, and especially a detailed comparison between modular PLCs and compact PLCs.

6 major types of PLC and their differences

PLCs are classified into 6 different types based on their size and use such as Mini PLCs, Compact PLCs, Modular PLCs, Safety PLCs, Micro PLCs, and Nano PLC

Mini PLCs

Mini PLCs

This is very small and low-cost which is extremely suitable for simple, less complex control applications.

The input/output (I/O) points of this type are usually very few and can still be programmed in other programming languages without any problems. In addition, it can be installed quite quickly due to its small size and I/O capabilities such as digital input, analog output, and pulse output.

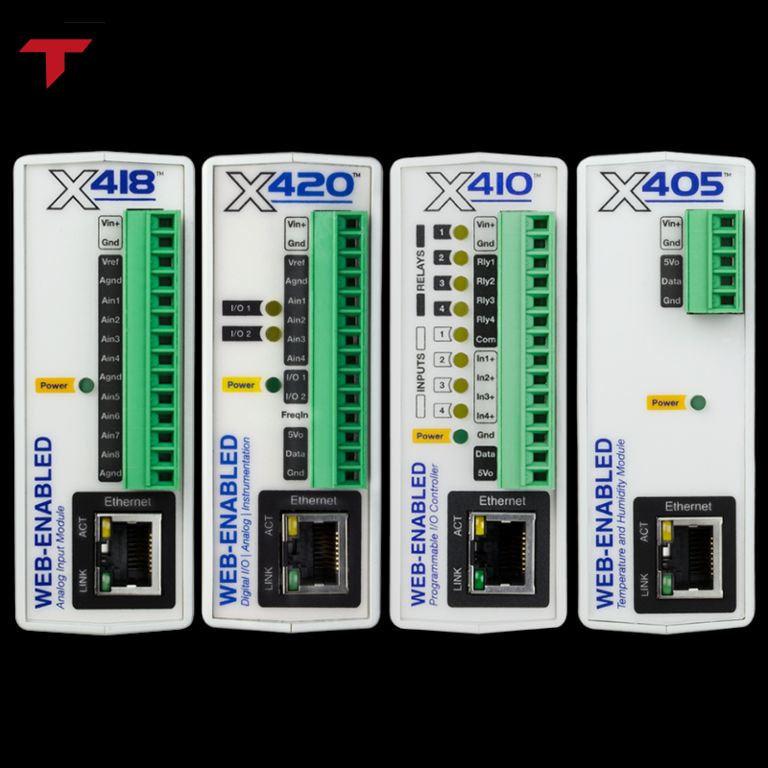

Fixed/Integrated/Compact PLC

Fixed/Integrated/Compact PLC

The most common type of PLC is called I/O PLC. I in Input and O in Output, specifically ‘Fixed I/O’ is understood as ‘Fixed Input/Output’, meaning the devices are already connected at the input and output. In this way, you can monitor exactly what the PLC is doing in your factory.

Please note that increasing the number of inputs or outputs will not expand this type of PLC.

Modular PLC

This type of PLC will be able to add or remove modules from the system, increasing the scalability and meeting more automation requirements for the factory. However, to create a PLC control system, all the components such as the Communication Module, and Input/Output Module with microcontroller, need to be manually connected to the power supply.

You know the modular PLCs are designed in different sizes, with different power supply speeds and different computing capabilities:

- Small PLC: This is a compact PLC, which is used to replace wired logic, counters, and timers. The only drawback of this type of PLC is the maximum module limit of 2 modules.

Small PLC

- Medium-sized PLC: Mid-sized PLC is more advanced and popular than the previous types, because of its simplicity, it allows for multiple modules to be plugged in and can provide hundreds of I/O information through multiple cards without any problems

Medium-sized PLC

- Large PLC: Advanced PLC the most complex control functions, with higher capabilities of the modules in this type are higher than the previous two types of PLC. Usually, factories with monitoring and data acquisition systems will use this type of PLC.

Large PLC

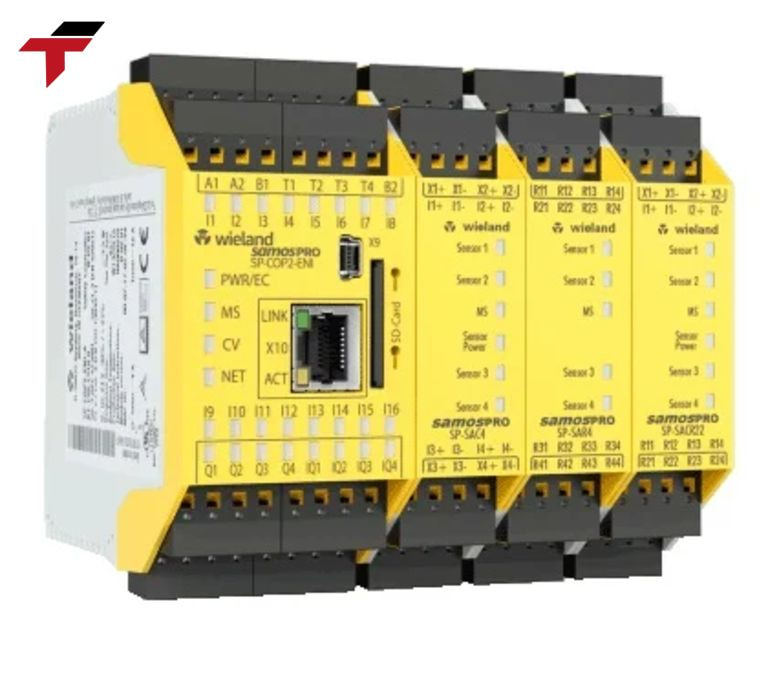

Safety PLC

Safety PLC

Fail-safe PLC was created to ensure safety in industrial automation functions, this type of PLC plays a major role in protecting equipment and the environment through standards such as IEC. However, it is necessary to follow guidelines and be assigned a safety integrity level (SIL) to increase reliability and risk tolerance…

Micro PLC

Micro PLC

The biggest advantage of Micro PLC is that the devices are capable of controlling processes at the same time without the need for expansion cards or price support. It also has additional communication functions for easier integration into automation systems

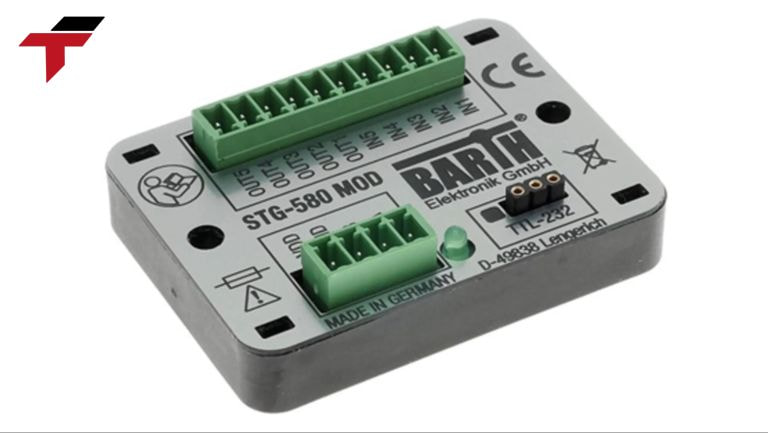

Nano PLC

Nano PLC

The final PLC type is the Nano PLC – the latest generation of control controllers. These are ultra-compact and combined with dedicated software installation programs to reduce costs while still ensuring very high processing speed and accuracy. This type of PLC is especially used in quite complex applications and involves multi-axis movements or pattern matching.

What are the advantages of PLCs in Industry?

Since 1968, after PLC was successfully invented, it has become the optimal choice for manufacturing processes for the following reasons:

- Cost Savings: PLCs may have a higher initial cost than traditional relay-based systems, but they offer significant cost advantages over time as PLCs are often more cost-effective in the long run due to their lower maintenance requirements and longer lifespan.

- Ensure reliability: PLC ensures reliability in machine control, so it is relatively easy to install many different programs into the PLC control system. In particular, the entire program processing is in the PLC’s memory, so the possibility of errors is impossible.

- Reduce downtime: The PLC control system manages the process in real time, saving significant time in production. To this day, PLCs are considered the controllers that can help the production process be carried out quickly and accurately.

- Easy Installation and Maintenance: PLCs are designed and built for easy installation and maintenance, which is a major benefit that makes troubleshooting (if any) easier.

- Remote Access: Many modern PLC systems can solve the problem of remote access to machines without having to be physically present, making monitoring and troubleshooting easier.

What Is the Difference Between a Modular PLC and a Compact PLC?

The choice of PLC module or compact PLC depends on the technical specifications that the customer wants for their production line project.

| Compact PLC | Module PLC |

| Challenges with complex repairs | Easy maintenance process |

| Fixed I/O count | Users can install different modules, more flexible and scalable architecture |

| Multiple options: consolidated or fixed PLC | Only rack system PLC |

| Available I/O page with CPU | Allows custom I/O configuration by adding or removing modules as needed |

| Limitations in data storage | Featured with larger memory capacity |

| Suitable for home use or small spaces | For industrial use and future expansion |

| Low cost and small size | Cost and size are larger than Compact PLC |