A pneumatic Cylinder, also known as a pneumatic cylinder, is an important device in the pneumatic system, helping to convert energy from compressed air into mechanical movement.

With a simple structure, high efficiency, and the ability to work in many harsh environments, Pneumatic Cylinder is widely used in industries such as automation, machine manufacturing, and food production. Let’s learn with FLEXTECH about the structure, classification, and choosing the right pneumatic cylinder for your needs.

Introduction to Pneumatic Cylinder

What is a Pneumatic Cylinder?

Pneumatic Cylinder is an important device in the pneumatic system, used to convert pneumatic energy into mechanical motion.

In industrial automation systems, pneumatic cylinders play a decisive role in the operation and control of mechanical equipment.

Pneumatic Cylinders can operate in many different conditions and is applied in production lines, packaging, food processing, the automobile industry, machinery and equipment manufacturing,…

How many common types of Pneumatic Cylinders are there?

There are three main types of Pneumatic Cylinders, each with its own characteristics and applications: Pneumatic Cylinder Single-Acting, Pneumatic Cylinder Double-Acting, Pneumatic Cylinder Rodless

Pneumatic Cylinder Single-Acting

Pneumatic Cylinder Single-Acting operates when compressed air is applied to only one side of the piston. The piston moves in one direction when compressed air is applied, and is then returned to its original position by a return force (usually a spring). This type is simple and cost-effective but is only suitable for applications that do not require the piston to move in both directions.

Pneumatic Cylinder Double-Acting

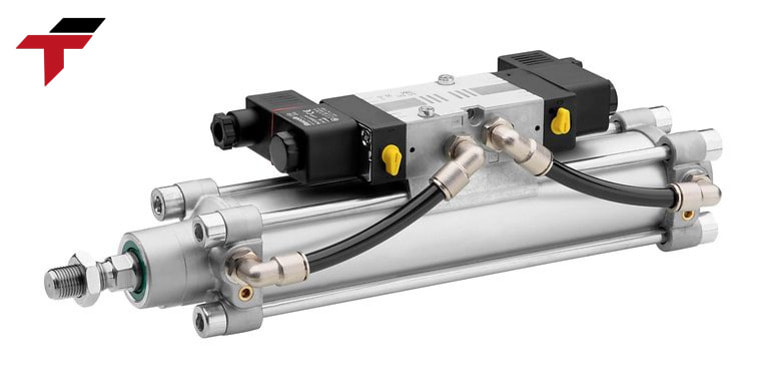

Pneumatic Cylinder Double-Acting is capable of operating in both directions, thanks to two pneumatic ports, one on each side of the piston. When compressed air is applied to one side of the piston, it creates a one-way movement, and when compressed air is applied to the opposite side, the piston moves in the opposite direction. This type of cylinder is popular in applications that require strong and continuous force.

Pneumatic Cylinder Rodless

Pneumatic Cylinder Rodless does not have a slide like other types, instead, it uses a special operating system to help the piston move without the need for a guide rod. This type is often used in applications where there is no space to install a cylinder with a slide or a long stroke is required.

Classification of Pneumatic Cylinder

What are the advantages and disadvantages of a Pneumatic Cylinder?

Pneumatic Cylinder is widely used in pneumatic systems thanks to its simplicity and efficiency in converting pneumatic energy into mechanical motion. However, like any industrial device, Pneumatic Cylinder also has its own advantages and limitations.

Understanding these characteristics will help you maximize the benefits of the device and apply it appropriately in specific applications.

Advantages

- Low cost: Pneumatic Cylinder is an economical solution for applications that require powerful mechanical motion without requiring complex equipment.

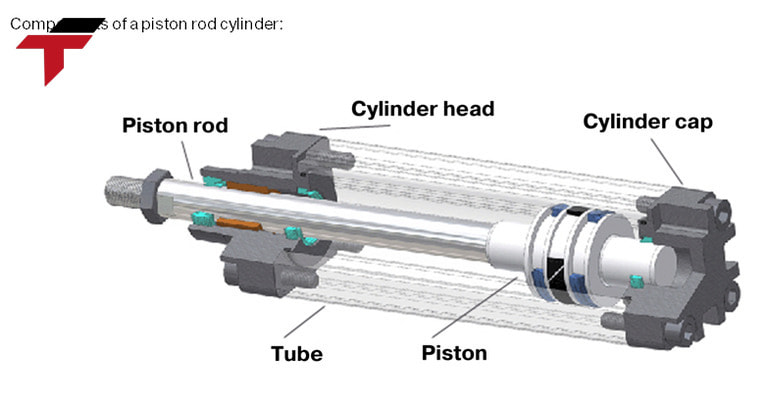

- Easy maintenance: Pneumatic Cylinder has a simple structure, easy to maintain and replace damaged parts.

- Operating in harsh environments: Because it uses compressed air, Pneumatic Cylinder can work in environments with high humidity, changing temperatures or where electric motors cannot be used.

- Safety: Pneumatic systems are safer than electric or hydraulic systems, as compressed air does not cause explosions or pose a risk of leakage.

Disadvantages

- Requires a compressed air supply: Pneumatic cylinders only operate when compressed air is available, which requires a properly maintained and supplied pneumatic system.

- Limited force: Although Pneumatic cylinders can produce strong forces, compared to hydraulic or electric cylinders, the force they produce may be more limited in some special applications.

Advantages and disadvantages of Pneumatic Cylinder

What are the considerations when choosing a Pneumatic Cylinder?

Choosing the right Pneumatic Cylinder plays an important role in the operational efficiency of the pneumatic system.

An unsuitable cylinder can waste resources, reduce work efficiency, or even disrupt the entire production line.

To ensure the stable operation of the equipment and meet technical requirements, the following are important factors you need to consider when choosing a pneumatic cylinder.

- Piston size and stroke: Depending on the application, you need to choose a cylinder with the appropriate piston stroke and reasonable size.

- Working pressure: The compressed air pressure will directly affect the impact force of the cylinder, so it is necessary to choose a cylinder that can withstand the working pressure suitable for the system’s requirements.

- Material and corrosion resistance: In applications in harsh environments, choosing a durable, corrosion-resistant material is very important.

In which industries are Pneumatic Cylinders used?

Pneumatic Cylinders are widely used in many industries thanks to their flexibility and efficiency:

- Industrial automation systems: In automatic production lines, Pneumatic Cylinders help control the movement of machinery and equipment, from transporting materials to opening and closing valves, box lids, etc.

- Food packaging and processing: Pneumatic cylinders help move products in packaging or food processing systems, minimizing human intervention and increasing productivity.

- Automotive industry: In the automotive manufacturing industry, Pneumatic Cylinders are used in stages such as assembly, quality control, welding robot operation, etc.

- Machinery and equipment manufacturing: Pneumatic cylinders also help machinery and equipment operate more smoothly and quickly in applications requiring high precision.

Application of Pneumatic Cylinder

Conclusion

Pneumatic Cylinder is an important component in the pneumatic system, widely used in industries and automation. With a simple structure, easy maintenance and reasonable cost, a Pneumatic Cylinder helps optimize production processes, increase efficiency and minimize risks. Proper selection and maintenance of the Pneumatic Cylinder will help the system operate stably and durably for a long time.