Yaskawa Servomotors

Yaskawa Servomotors Support Global Manufacturing Automation

If you look inside your everyday smartphones, tablets, computers and home appliances, you can see that they are made up of hundreds of different components, including electronic components, semiconductor chips, batteries and cameras etc. When manufacturing these, companies try to automate by installing industrial robots and machine tools to maintain high quality while increasing production efficiency. Servomotors are often used to enable such machines and industrial robots to perform ultra-high-speed, ultra-precise motion such as right to left or up and down.

Servomotors are not seen in everyday life, but they are “motors that are good at stopping at the position indicated by a comma several millimeters”, and they are important parts that must be used as power for factory automation. The positioning accuracy is such that, for example, when the motor is rotated the circumference of about 40 km, it can detect and control the error of the moving 4 mm.

Since Yaskawa invented the world’s first prototype Minertia motor in 1958, AC servo motor has led the factory automation industry with a global market share of No. 1, with cumulative shipments exceeding 20 million units. We would like to introduce what kind of industry servomotors are contributing to.

A motor is a generic term for a motor that converts electrical energy (electricity) into mechanical energy (motion), and a servomotor refers to a motor with excellent controllability. “Excellent controllability” refers specifically to the ability to faithfully follow commands from the host controller. This is achieved by characteristics such as high starting torque, high responsiveness, and high speed stability.

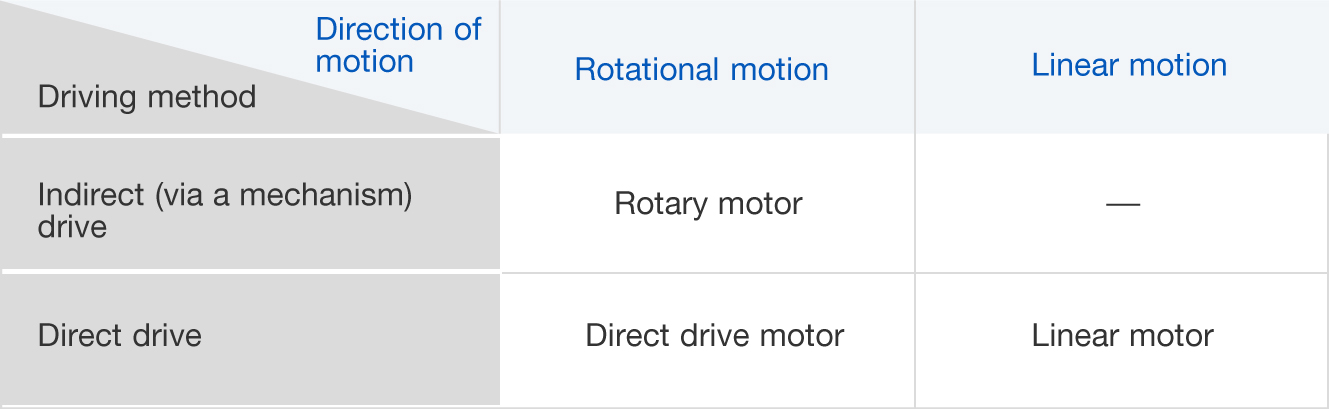

Servomotors can be classified according to the driving method and direction of motion as shown in the table below.

Servomotors come in various sizes, and the required force (torque) is determined by how fast you move a heavy object, and you need to choose a motor that can produce that torque. Yaskawa offers motors with optimal shapes and capacities to meet customer needs.

The basis of rotary servomotor is a rotary motor, which converts electrical energy into rotational motion, as its name stands for. The configuration of a rotary motor is divided into a rotor section, which rotates greatly, and a stator section, which supports the rotating section. It is common to use a mechanism such as a coupling, ball screw, cam, or pulley with a control object that is under a load to be moved. Yaskawa offers a wide range of products, from 3.3 W ultra-compact models with low inertia and small capacity that can be held in the palm of the hand to 55 kW models with medium inertia and large torque.

Direct drive motors are one of the rotary motors, but in order to drive the control target directly, the maximum rotational speed is lower than that of rotary motors (several 100 rpm), but on the other hand, they can output high torque even at low speeds. As a result, there is no backlash or loss of mechanical parts, enabling high-precision control.

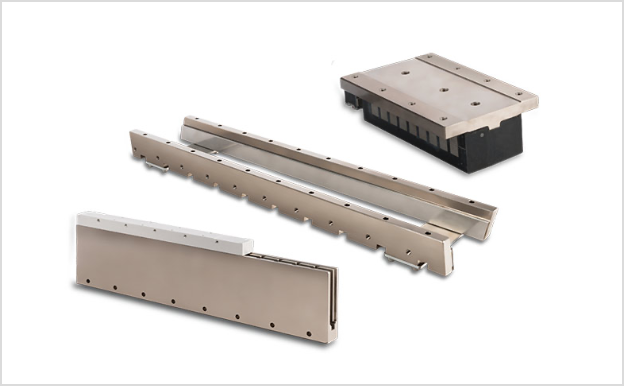

A linear motor also drives the controlled object directly, but it moves in a straight line rather than in a rotary motion (similar to a linear motor vehicle). Linear motors are also divided into moving parts and stationary parts. The moving parts are called movers, and the stationary parts are called stators. The linear motor combined with a linear scale (detector) and a guide supporting the drive is called a linear slider.